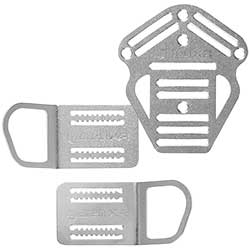

Hardware

Hardware and Softgoods

Aluminum vs. Stainless Hardware

Aluminum hardware is almost one third of the weight for similar stainless steel hardware. Although stainless is stronger, in practice there is not much difference in terms of durability or corrosion resistance for backplates and harness hardware. Cosmetically, aluminum can be anodized many different colors and some divers like the stealth look of black anodized aluminum while others like the polished look of stainless. Depending on the brand, an aluminum backplate has a dry weight of about {3 lb} less than an identical design in stainless steel. A full set of typical harness hardware such as D-rings, slides and buckles in aluminum will weigh roughly {0.5 lb} less than identical hardware in stainless steel.

Divers will often choose aluminum when they are diving heavier steel tank configurations and have already shed as much weight as possible off their waist. Divers using a single AL-80 tank and especially AL-80 doubles or diving in drysuits, will benefit from choosing stainless steel. A secondary consideration is often about in-water trim. Many divers trim can benefit from redistributing weight from their waist to their back, so again stainless backplates are preferred in those circumstances.

Your choice as a diver is not critical because in-water the total weight difference is less than {4 lb}, so frequent flyers often choose aluminum over all other considerations when they want to travel as light as possible. It's relatively easy to add lead at the boat, but it's difficult to reduce the weight of your luggage at the airport.