Gas - Tanks

Cylinders, Tank Straps and Bands, Valves, Gas Analyzers and Accessories

WARNING

WARNING

Give Tank Boots the Boot, Decals Too!

Tank boots aren't available for most of the aluminum tank sizes we sell because tank boots are only made for 6.9 inch(AL-72), 7.25 inch(AL-80) and 8.0 inch (AL-100) tank diameters. Aluminum tanks don't need boots because they have flat bottoms and so we don't include tank boots on aluminum cylinders in those diameters for a very good reason: they are the most common cause of external corrosion damage to the tank and most experienced divers don't use them on aluminum tanks.

Tank boots on steel cylinders are necessary because steel cylinders always have a round bottom and unless the cylinders have a boot they won't stand up on their own without using something to secure them. The rigid thermoplastic boots from Sea Pearls that we include with the high pressure F7 and F8 cylinders are stable and drain reasonably well. However, we dislike the soft vinyl boots supplied by Blue Steel for the low-pressure LP-85 and LP-50; unfortunately nothing else is available but the soft vinyl versions are notorious for causing external corrosion under the boot on Faber cylinders because they do not drain well. The soft vinyl boots are also relatively unstable (the LP-50 is dangerously unstable and we don't include it by default.)

If you must have a boot on your tank, then when you get home from the dive knock the boot off then rinse the tank and boot. Leave the boot off until everything is dry, then replace the boot and store the tank standing upright until the next time to go diving.

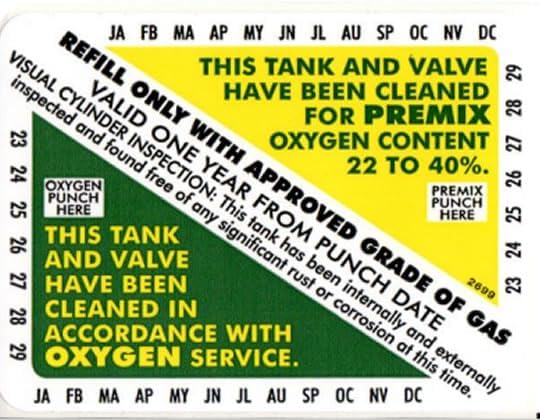

Another common reason we see for cylinders failing their annual inspection and being condemned is corrosion beneath decals. Some decals like the VIP sticker, MOD, and Nitrox decals are necessary, but those should be the only decals on your tanks. Decals (including those big 'Nitrox' decals) should be scraped off every year during inspection. If your local dive shop takes the time to remove all decals, then you know they are protecting your investment. Only the required decals should be replaced, a single current VIP decal and if necessary a nitrox wrap or MOD decals.