Aluminum Tanks (Cylinders)

Only aluminum tanks on this page, or visit Steel Tanks (Cylinders).

For rebreathers, visit CCR Cylinders & Valves

-

Thunderbird AL-80 Cylinder, Brushed No-CoatAs low as $269

Thunderbird AL-80 Cylinder, Brushed No-CoatAs low as $269 -

Thunderbird AL-72 Cylinder, Natural FinishAs low as $269

Thunderbird AL-72 Cylinder, Natural FinishAs low as $269 -

Thunderbird AL-40 Cylinder, Brushed No-CoatAs low as $229

Thunderbird AL-40 Cylinder, Brushed No-CoatAs low as $229 -

Thunderbird AL-30 Cylinder, Brushed No-CoatAs low as $219

Thunderbird AL-30 Cylinder, Brushed No-CoatAs low as $219 -

Thunderbird AL-19 (Tall) Cylinder, Brushed No-CoatAs low as $189

Thunderbird AL-19 (Tall) Cylinder, Brushed No-CoatAs low as $189 -

Thunderbird AL-13 Cylinder, Brushed No-CoatAs low as $159

Thunderbird AL-13 Cylinder, Brushed No-CoatAs low as $159 -

Thunderbird AL-6 Cylinder, Brushed No-CoatAs low as $139

Thunderbird AL-6 Cylinder, Brushed No-CoatAs low as $139 -

DGX Custom - Aluminum Cylinder Sidemount PackagesAs low as $509

DGX Custom - Aluminum Cylinder Sidemount PackagesAs low as $509 -

DGX Custom - AL-80 Doubles PackageAs low as $859

DGX Custom - AL-80 Doubles PackageAs low as $859

WARNING

WARNING

Lubrication and SCUBA Valve Installation

In general purpose applications, the lubrication of joining threads will reduce galvanic action between dissimilar metals and when joining tapered threads is useful to reduce galling. This is especially true when the very tight join alone is responsible for providing a seal. Aluminum metal is notable for it's susceptibility to galling. Lubrication of O-rings helps protect against wear, abrasion, pinching, or cutting. As a result, conventional wisdom and "common sense" says to always lubricate threads and O-rings. However, the benefit of using lubrication during installation of valves in SCUBA cylinders is debatable.

In our own experience, we find no need for lubrication with properly maintained SCUBA tanks where the valve is removed and O-ring seal replaced on the annual VIP maintenance schedule recommended by our industry. SCUBA valves already have a relatively low potential for galvanic action due to the inherent nature of their materials. Modern SCUBA valve inlet threads are straight, not tapered, and galling (even in aluminum cylinders) is not a concern unless the valve is improperly over-tightened into the cylinder neck. The threads are not intended to provide a seal in this application; the high-pressure seal is provided by a captured O-ring. The unique design of the captured O-ring seal between the SCUBA valve and cylinder neck will not damage the O-ring during assembly, nor is it subject to wear. While oxygen compatible lubrication of the neck threads and O-ring in SCUBA valves and cylinders is harmless when done correctly and under ideal conditions, it also has no clear benefit.

Generic cylinder and valve maintenance guides rarely address the specific nature of the SCUBA industry, especially in regards to gases other than air. Since the valve, O-ring, cylinder and lubricant manufacturers in any assembled SCUBA tank are all different, it's commonplace to find conflicting recommendations. Even gas handling standards and best practices regarding use of lubricant have conflicting recommendations. Our suppliers do agree that nearly all installation, sealing and removal problems are caused by improper technique and over-tightening the valve into the cylinder, as well as often the excessive use of lubricant but very rarely the absence of lubricant. A few local dive shops intentionally avoid all lubricant, some use it very sparingly and many others use it to excess. The bottom line is that lubrication use in this SCUBA application seems to mostly be a matter of opinion derived from parsing conflicting standards and confusing recommendations.

Any lubrication, even oxygen compatible lubrication, is typically not considered best practice for use with medical oxygen or industrial oxygen. That's because while oxygen compatible lubricants might have higher temperatures of ignition than hydrocarbons, they can still serve as fuel in the kindling chain of an oxygen fire. Any lubricant will attract and retain contaminates, plus there is the significant risk that an incompatible lubricant might be applied. In our opinion, legitimate oxygen safety concerns outweigh the questionable benefits espoused by those recommending lubrication in SCUBA cylinder and valve Nitrox applications.

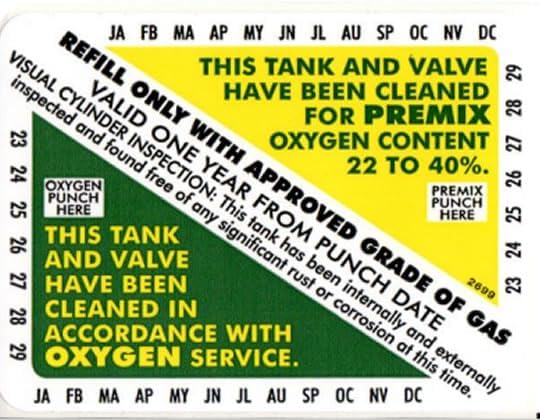

Prioritizing safety above all other considerations, Dive Gear Express does not recommend using any form of lubricant, including oxygen compatible lubricant, when installing our Nitrox Ready SCUBA valves in oxygen clean cylinders.