O-Rings - Lubricant - Tools

All oxygen compatible for SCUBA use.

-

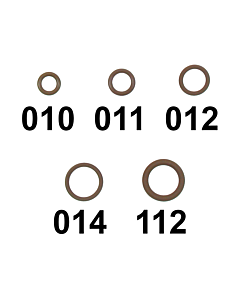

Fluorocarbon (FKM) O-Ring, Qty of FiveAs low as $3.00

Fluorocarbon (FKM) O-Ring, Qty of FiveAs low as $3.00 -

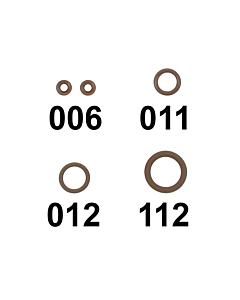

Apeks DIN O-ring, Qty of Ten$12.00

Apeks DIN O-ring, Qty of Ten$12.00 -

Tribolube 71 O2 Compatible LubricantAs low as $9.95

Tribolube 71 O2 Compatible LubricantAs low as $9.95 -

O-Ring Guide Tool Set$10.00

O-Ring Guide Tool Set$10.00 -

Compact Scuba Multi-Tool$21.00

Compact Scuba Multi-Tool$21.00

WARNING

WARNING

Designers of modern SCUBA equipment often specify O-rings with special properties and materials for specific uses inside their equipment. The special O-rings are supplied as part of original equipment manufacturer (OEM) service parts kits. Substituting any other generic O-ring just because it's the right size can cause difficult-to-diagnose problems and degrade performance. Improper service could cause a failure which would have serious and life threatening consequences.

Sizing and Selecting O-Rings for SCUBA

While it might seem convenient to provide a picture sizing chart, we've never seen an online version that could be reproduced exactly in a Web browser or a PDF version that could be reliably reproduced in a printer. Sizing an existing O-ring that has been in service can be error prone because O-rings can take a compression set that changes their dimensions enough to be misleading. Also, depending on their material and exposure to specific lubricants or gases, some O-rings will swell in size over time. Luckily, the sizes and materials used in 'user serviceable' SCUBA applications are fairly regular, so it's probably best to choose based upon the application.

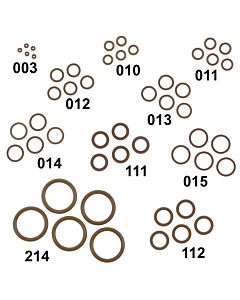

Sizing Nomenclature -- The Society of Automotive Engineers (SAE) publishes the AS568 (Revision "F" issued 2020) aerospace standard that defines imperial sizes for O-rings used in sealing applications. An AS568 number has a three-digit suffix that identifies the O-ring's physical size. Technically, an O-ring size is listed as AS568F-014, AS568F-112, AS568F-214 and so on, but most people use just the three-digit number. Sizes are specified by the inside diameter and the cross section diameter (thickness). The first digit denotes the O-ring cross section width: 0xx = 1/16-inch, 1xx = 3/32-inch, 2xx = 1/8-inch. British Standards Institution (BSI) publishes the BS ISO 3601-1:2012+A1:2019 standard that defines equivalent imperial sizes, so a BS3601-112 O-ring and AS568-112 O-ring are the same physical size. (The obsolete British imperial standard BS 1806 is still widely referenced, but was superseded by the BS ISO 3601 standard.) BS ISO 3601 also defines metric sized standard O-rings, for example M2.4X11.3 has an inside diameter of 11.3 mm with a 2.4 mm cross section.

Materials -- O-rings can be made of a variety of exotic materials, but some are inappropriate for SCUBA applications. ASTM International (ASTM), originally known as the American Society for Testing and Materials, publishes technical standards for O-ring materials. The materials commonly used in SCUBA applications appear in the following table.

| Material | Description |

| Acrylonitrile-Butadine Copolymer (NBR) |

Many O-rings used in SCUBA are made from NBR, the ASTM standard designation for a class of hydrocarbon based synthetic nitrile rubbers. Nitrile is also known as Buna-N, one of the first such materials that was patented in 1934 and often now used as a generic name. NBR is a widely used and low cost elastomer that offers good resistance to oxygen. |

| Fluorocarbon (FKM or FPM) |

FKM is the designation for a class of fluorocarbon based synthetic rubbers as defined by ASTM standards, equivalent to FPM by ISO standards. Originally developed by DuPont under the name Viton, FKM is an elastomer with excellent resistance to oxygen, although it has a tendency to swell slightly in the presence of high-pressure oxygen and can produce very toxic fumes during combustion. |

| Polyurethane (AU or EU) |

The translucent O-ring occasionally seen in the face of K-valves and DIN connectors, is made of polyurethane. Polyurethane has excellent oxygen resistance along with excellent abrasion resistance but it is sensitive to UV light (sunlight). The ASTM standard designation for most polyurethane in O-ring elastomers is AU for polyester urethane, or rarely O-rings are made from EU for polyether urethane; in general polyurethane is sometimes abbreviated PU. |

| Ethylene Propylene Diene Monomer (EPDM) |

EPDM class O-rings are becoming common in SCUBA because it is a less toxic oxygen compatible material for cost effective use in breathing gas systems. EPDM is an elastomer with excellent oxygen resistance and odor-free characteristics, although EPDM is not recommended for use with petroleum derivatives. |

| Silicone (VMQ) |

The rust color O-rings sometimes seen in rebreather loop seals are made of silicone. The term silicone describes a class of materials in which vinyl-methyl-silicone (VMQ) is the primary ingredient. VMQ is especially non-toxic, thus widely used in food service and medical applications. VMQ is not recommended with silicone based lubricants commonly used in SCUBA. |

Hardness -- O-rings are commonly available with a hardness rating, as measured by an ASTM type-A Shore durometer, of about 70 (softer) or more rarely a rating of 80 or 90 (harder). The harder O-rings are generally better suited to most of the SCUBA applications we describe. The softer O-rings are appropriate for dynamic applications where the O-ring is providing a seal with a moving part, such as inside swivels. The harder O-rings are more durable in static applications where the O-ring is providing a seal with stationary parts, such as hose fittings.

Color and Appearance -- O-rings are available in nearly any color, although most commonly seen in black regardless of material. There are no O-ring color coding standards and thus color is not an indication of the material or quality. The oxygen compatible O-rings sold by Dive Gear Express are usually brown, green, white or purple; simply to make them easily distinguishable from NBR O-rings which are usually black. O-ring materials also can not be distinguished from each other by their surface appearance, more a function of the manufacturer than the material. Just to be clear, the COLOR and SURFACE APPEARANCE of the O-ring is MEANINGLESS regarding their compatibility with oxygen.

Caution: O-rings made from Hydrogenated Nitrile (HNBR) class materials are commonly available due to their resistance to many automotive fluids as well as refrigerant gases and their color is often green. However, HNBR compatibility with oxygen is typically considered poor. Do not assume an O-ring is suitable for use with Nitrox just because the color is green.

Shelf-Life -- The Society of Automotive Engineers (SAE) publishes ARP5316 (Revision "D" issued 2014) as the recommended practice for the storage of O-rings. It states the shelf life prior to use of PU material O-rings is 5 years, NBR material O-rings is 15 years and the shelf life of FKM/EPDM/VMQ material O-rings is "unlimited".

Counterfeits -- The O-ring industry sees a lot of products that do not meet their material specifications, substituting cheap or low quality materials for more expensive fluorocarbons and coloring them brown or green. Counterfeit and mislabeled FKM O-rings are so widespread that Dive Gear Express makes up our own kits using O-rings supplied through trustworthy channels.

Lubrication -- Oxygen compatible PFPE/PTFE based lubricants such as Tribolube 71 are compatible with all elastomer materials commonly seen in SCUBA. Oxygen compatible lubricants are generally considered best practice within the SCUBA industry as they will typically outperform silicone grease and are also much less migratory. The use of petroleum based lubricants like mineral oils should generally be avoided with SCUBA equipment because of the now widespread use of EPDM materials.

Dive Gear Express stocks a variety of O-rings for SCUBA diving Nitrox applications along with lubricant and tools.

Our first SCUBA TekTip, this text was originally ©Copyright 2004 and substantially revised ©Copyright 2018, 2021 and 2025.