Inflator Service Tool with O-Ring Kit

- Disassemble and service your Power Inflator with this complete kit

- Tool has three openings that are compatible with most tek BC aircells

- Includes a complete set of oxygen compatible replacement O-rings

- Watch the video above for exact instructions BEFORE you perform service

- NOT compatible with Aqualung, Cressi, Genesis, Mares, Oceanic, and ScubaPro

Inflator Service Tool with O-Ring Kit

The stainless steel Inflator Service Tool has three openings that allow easy disassembly of the widely used generic power inflators found on most tek BC aircells including those from Dive Rite, Halcyon, Highland, HOG, Hollis, IST Dolphin, Light Monkey, OMS, OxyCheq, White Arrow and others. The tool will NOT work for proprietary inflators as found on Aqualung, Cressi, Genesis, Mares, Oceanic, and ScubaPro; those inflators are not user serviceable. The tool includes a complete set of replacement oxygen compatible O-rings.

Included in the kit:

- 1/2" hex wrench for the low pressure quick release nipple

- Special spanner with two bent tangs which fit the slots in the inlet valve cartridge assembly and facilitates its easy removal

- 3/8" hex to keep the end of the valve spool in place while removing the plastic button from the cartridge valve assembly

- Handwheel nut driver used to service scuba valves

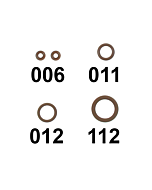

- Includes the five O-rings found in the power inflation mechanism: 112-V90B, 012-V90B, 011-V90B, and two 006-V75B

The manual exhaust is not pressurized and operates independently of the power inflation mechanism. On some designs it requires an uncommon deep well socket tool for disassembly. We don't recommend disassembling the manual exhaust assembly, and so we don't include the #110 manual exhaust O-ring in the kit.

| Brand | DGX |

|---|---|

| SKU | DX-82002KIT |

| Weight | 0.600000 |

Customer Reviews

WARNING

WARNING

The power inflator service tool, o-ring kit and overhaul instructions are a 'save-a-dive' solution for qualified professionals but our recommendation is to replace, not service, your power inflator if it develops any problems. Improper service could cause a failure of buoyancy control, which has serious and life threatening consequences.

The History Behind the K-inflator and Drift-Pin vs. Schrader Inflators

The "K" shaped drift-pin design inflator found on buoyancy control aircells (aka wings) in the technical diving community was originally designed and made by the late Larry Scott of Huntington Beach, CA in the 1970s. Today there are many manufacturers of K-inflators and some of them just copy Larry’s original design. In that design, a dynamic o-ring rubs against a v-cut opening at the end of the valve. This creates additional wear on the dynamic o-ring so to mitigate wear the design relies upon a firmer Shore-A90 durometer o-ring. In some more recent K-inflator designs, the sealing o-ring does not rub against the v-cut opening and instead just touches on a flat opening at the end. With this change, the inflator can use a common Shore-A70 durometer softer rubber o-ring.

The original design K-inflator (or the equivalent copies) could be unsafe if improperly serviced and can be identified by the hex nut protruding from the end of the inflator cartridge. A potential life-threatening hazard might occur if the service technician, or a diver, repairs a leaking original Larry Scott design K-inflator or equivalent copy by substituting softer o-rings. There is a risk of the softer o-ring being blown out of position and extruding out the end of the cartridge. See the photo for an example - when this happens, the inflator may become stuck open and rapidly inflate the BCD with a subsequent loss of buoyancy control! Statistics from DAN suggest that a failure of buoyancy control can be one of the most life threatening types of dive accidents.

The K-inflator sold by Dive Gear Express and others such as the Highland brand are the improved version with a slotted screw head on the end of the cartridge. Unfortunately, you can't be sure what you have unless you remove the cartridge from the body of the inflator for inspection. This is the reason Dive Gear Express recommends just replacing, rather servicing, any leaking inflator. (However our "save-a-dive" K-inflator service kit does include the firmer Shore-A90 o-rings in nitrox compatible Viton.)

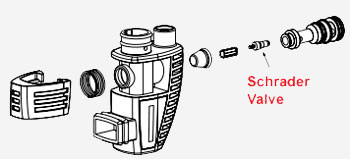

With his drift-pin design, Larry was solving a problem that is common to sport diving power inflators and the reason the K-inflator has been almost universally adopted by technical divers. The power inflators seen on many (probably most) sport diving BC jackets are based on using the Schrader valve; see illustration of a typical sport diving inflator design. Schrader valves are a tiny off-the-shelf assembly which corrodes easily, plus in this application they often get salt deposits caked in their springs. Unless meticulously maintained, they eventually do not seal fully closed and then dribble gas into the BCD. This results in the diver finding themselves gradually becoming inexplicably buoyant and requires periodically dumping gas from the BCD even though none was added by the diver. Compared to the Schrader valve design inflators, the benefit of using Mr. Scott's drift-pin valve design in his K-inflator is the improved reliability.

Want to check your power inflator for a leak? Setup your BCD and regulator on a tank with at least {300 psi | 20 bar} remaining then open the tank valve to pressurize the regulator. Make sure the low-pressure BC inflator hose is firmly connected and the over-pressure relief & dump valve on the BC is working, then use the oral mouthpiece on the inflator to suck out all the gas in the BCD bladder. Let the entire rig sit overnight. If you return in the morning to find your BCD inflated then your power inflator is leaking and should be replaced.